Welcome to the first in a series of brief articles about safety controls in Facilities Management (FM), where we work hard to keep our workplace safe and healthy for everyone. While personal protective equipment (PPE) often gets the spotlight, it's just one piece of the puzzle. In FM, we employ a range of safety measures that offer even greater protection than PPE alone.

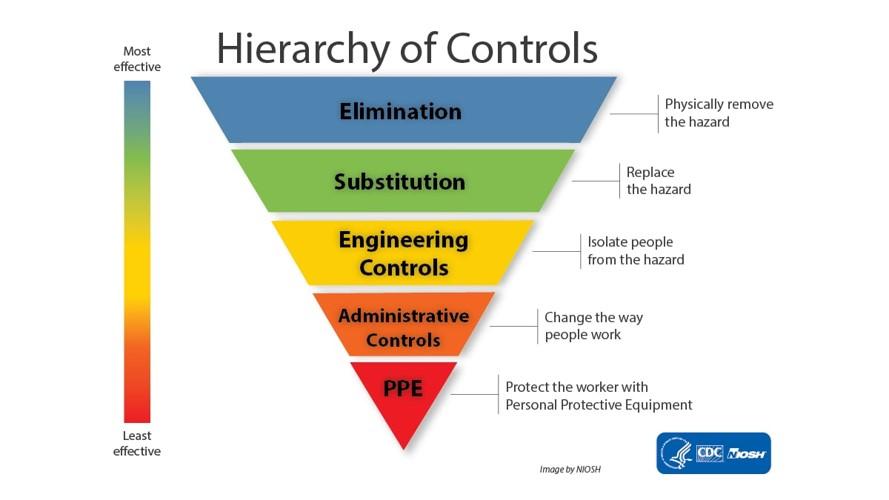

To guide our approach, we use something called the Hierarchy of Controls—a system safety professionals rely on to select and implement the most effective safety measures. This hierarchy is typically shown as an upside-down triangle, with the most effective safety controls at the top.

In this series, we'll explore each of the five levels of the hierarchy. Let’s start with a brief introduction to each, followed by deeper dives in future articles, where we’ll showcase examples specific to FM.

- Elimination Controls

Eliminating hazards is the most effective way to improve workplace safety. This often involves significant structural changes or equipment upgrades. For instance, one common elimination control in FM is the removal of asbestos-containing materials, effectively removing the risk altogether. - Substitution Controls

When elimination isn’t possible, substituting a safer alternative can reduce risks. In FM, we have replaced more hazardous cleaning products with those that are less toxic or harmful. Similarly, using tools with integrated dust control systems instead of those that generate dust can greatly reduce exposure to harmful particles. - Engineered Controls

Engineered controls involve physical changes that isolate or guard hazards. Examples include installing guardrails around rooftop edges to prevent falls or adding platforms to improve access to equipment on roofs. FM is also involved in supporting safety measures for university research, such as installing interlock systems in labs to prevent entry during hazardous experiments. - Administrative Controls

Administrative controls change how we work to improve safety. This could include scheduling outdoor work during cooler parts of the day to avoid heat stress or providing targeted safety training based on specific job tasks. Administrative controls often work hand-in-hand with other safety measures by helping manage hazards more effectively. - Personal Protective Equipment (PPE)

While PPE is often the most visible safety measure, it’s actually considered the last line of defense. PPE like safety glasses, gloves, and respirators are essential, but they don’t eliminate or reduce the hazard itself—they only protect the worker from exposure. In FM, we provide PPE tailored to each employee’s job tasks, ensuring it fits properly and works in conjunction with other safety controls.

In the coming articles, we’ll dive deeper into each of these control levels, highlighting specific ways FM is using them to keep our workplace safe. Stay tuned!